NEW Craftsman Edition 4” Perfect Spoon Knife 80CrV2 Mulberry Handle

NEW Craftsman Edition 4” Perfect Spoon Knife 80CrV2 Mulberry Handle

This is a very small Pre-Order of only 6 available knives with a quick turn around. The shipping date is Friday 27th.

The premise of the Craftsman Edition tools is user oriented simplicity in cost conscious offerings . I happen to put a lot of thought into this one so I landed with a tool that is both simple and super exciting to me.

It starts with the trusted carbon steel 80CrV2 profile ground to perfection of fine tip and progressive belly. No chance you’ll get a “good one” or “bad one” here, they are all identical. What you see in the picture for blade profile is what you will get! No flat spots or snubbed tips! The blade thickness is 2.8mm consistent.

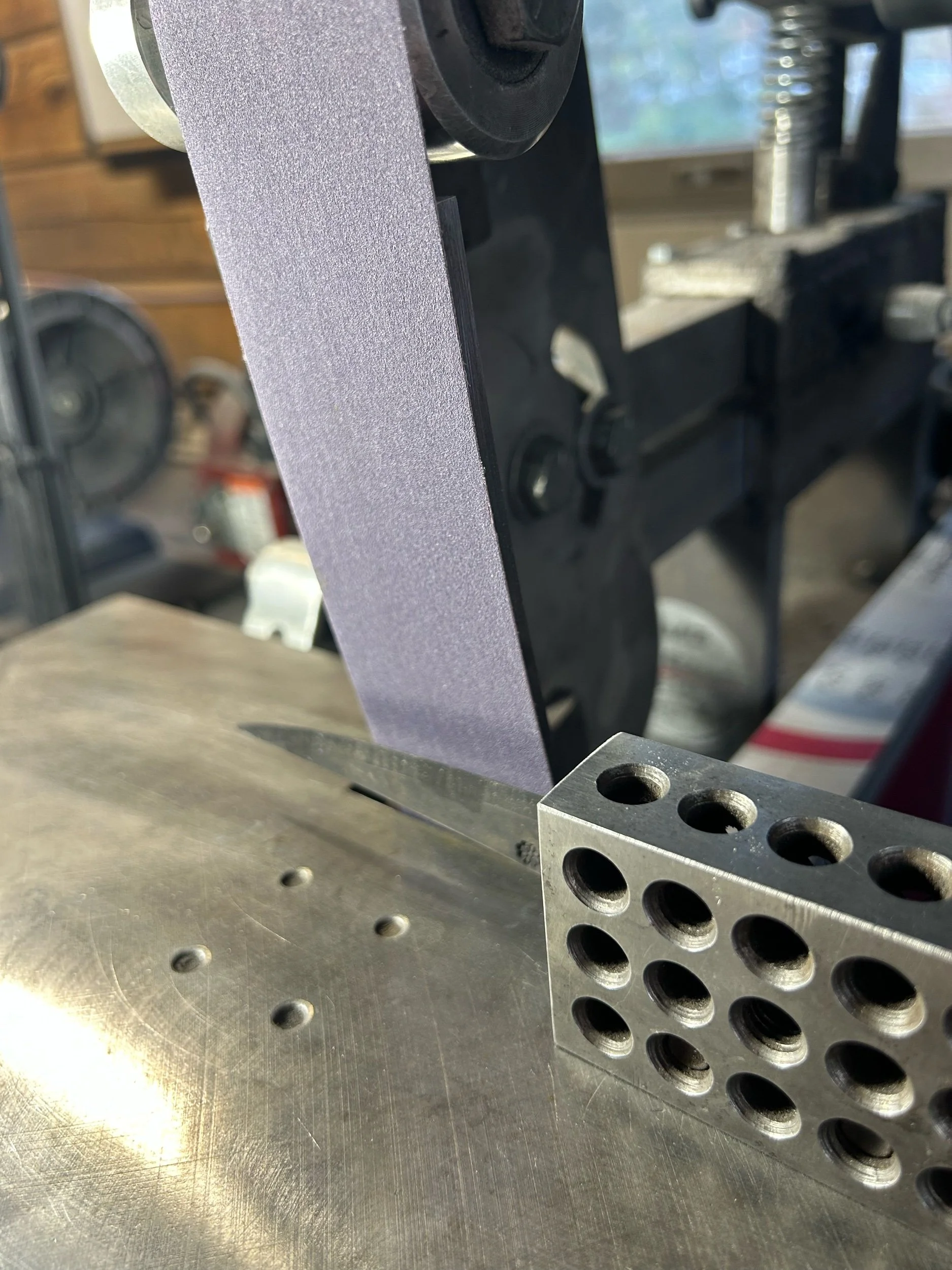

The Grind on this one is an industry first radius platen ground pure hollow. This is very exciting to me, so much so I included a couple pictures of the system I built for the nerdy types. Hollow grinds have always been done on a wheel typically in the range of 8” - 12” diameter. In order to perform as a carving knife you have to put a flat over the top of the hollow or the grind will be both too “grabby” and to fragile. Flat grind are typically done on platen, or stiff hard flat backing. I built a curves platen which essentially mimics the surface you would get from an impossibly large 15 foot wheel. The result is the best of both worlds, and some added control in my grinds (I’ll talk about that separately. The hollow is almost imperceptible and you will think it’s flat. It’s ready to carve and my hope is that with good care you’ll be able to go some time using only strops to maintain. The slight hollow helps to fight the dreaded convexing as you strop. You can use coarse black compound on this one and with good technique stay clear of over convexing.

The radius platen also makes it possible for me to do some creative things with the bevel angle design. By manipulating the knife in my grinding jig I can produce a progressive grind that is 27 degrees at the tip and 25 degrees at the handle end. Effectively I can create a roughing and finish edge in one tool. The 27 degrees at the tip will turn a little better and cut with greater delicacy, while the lower 25 degree will cut across grain with greater ease.

The 80CrV2 is heat treated in my Evenheat Kiln for precise control required for the best heat treats on the market (something I’m known for, I spend so much more time getting it right than my competitors). The blades all get a sub zero post quench treatment and are tempered to perfection.

The handles on these are five inches long. They are egg shaped in cross section with 12 facets. Mulberry is my choice this round! They are large enough for big hands to appreciate, and the smaller hands can either slim the handle down themselves, or ask me to do it for you! Make sure we connect if you want a small handle before you see the shipping notification.

Functional edge protection included. It’s not fancy.